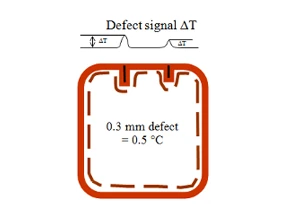

The IR scanner is the most important component in Therm-O-Matic®.

The line scanner is specially developed with functions only required for this application. The components are according to military specfications with high reliability. More than 100 units of the IR-scanner have been built. Some of them have been running continuously for more than 25 years, and still operates with the same performance today. We are very proud of the track record of our scanner.